This equipment is suitable for products within 5ml to 3ml including: cigarette oil bottle, cosmetics, mineral water, edible oil bottle, pesticide bottle, space cup, small jar, honey bottle, automobile industry glass water and other products. Suitable for pet, Pete, petg, PS, PC, PP, tri tan, ABS and other materials.

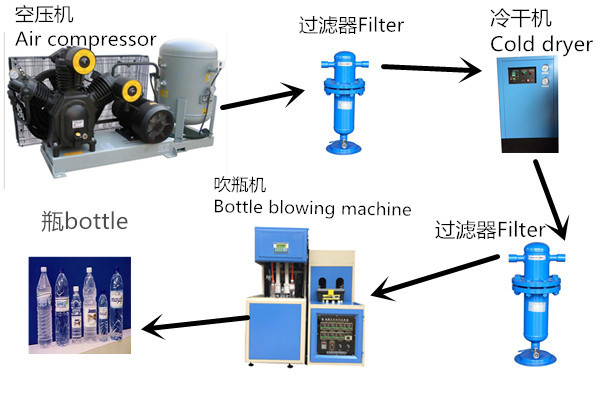

Process of blowing bottle

TX-3L 2-cavity technical parameters

Category | Item | Unit | TX2C3L | Finished product | material | / | PET | volume | L | 3L | theoretical output | PCS/h | 700-1200 | maximum height | MM | 350 | the largest diameter | MM | 115 | Template size | the largest acreage of template | MM | 360*410 | maximum thickness of mold | MM | 220 | minimum thickness of mold | MM | 90 | clamping force | T | 8T | mold opening stroke | MM | 155 |

Auxiliary

equipment | air compressor | 15KW | ¡Ý3.0/3.0 | air freeze dryer | 3.0 M pa | ¡Ý3.0/3.0 | air precision filter | 3.0 M pa | ¡Ý3.0/3.0 | Electric power of main engine | power | KW | 8 | voltage / frequency(three - phase) | V/HZ | 380/50-60 | working pressure | M pa | 0.8-1.0 | blowing pressure | M pa | 2.0-3.0 | Size | size of main engine | MM | 1700*640*1600 | heater size | MM | 1720*585*1360 | Weight | weight of main engine | KG | 550 | heater weight | KG | 260 | Note: as the company's equipment is constantly updated, the specific parameters shall be subject to the equipment! |

|